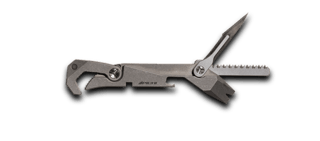

チタン製の日常携帯用 (EDC) ツールは、強度、軽量性、優れた耐久性を備えています。ただし、最も頑丈なツールであっても、一生使い続け、最高のパフォーマンスを発揮するには適切な手入れが必要です。このガイドでは、チタン製 EDC ツールのクリーニング、保管、メンテナンスの重要な手順を説明します。これらのヒントに従うことで、今後何年にもわたってギアを最高の状態に保つことができます。

適切なメンテナンスが重要な理由

チタン製の工具は耐腐食性と耐摩耗性に優れているため、日常的な使用に最適です。ただし、メンテナンスがまったく不要というわけではありません。定期的な手入れにより、次のことが保証されます。

-

長寿命:適切なメンテナンスにより、不必要な摩耗や損傷を防ぎます。

-

パフォーマンス:清潔でよくメンテナンスされたツールはより効果的に機能します。

-

美観:定期的に清掃することで、ツールは購入時と同じように美しい状態を保ちます。

ほんの少しの努力で、チタンギアの耐久性と信頼性を維持できます。

チタンEDCツールのクリーニング

ステップ1:掃除用品を集める

始める前に、次のアイテムを組み立てます。

-

中性洗剤またはチタンに安全な洗浄液

-

温水

-

柔らかい布またはマイクロファイバータオル

-

柔らかい毛の歯ブラシ

-

イソプロピルアルコール(粘着性の残留物用)

-

綿棒(届きにくい部分用)

ステップ2: 表面をきれいにする

-

温水ですすぐ:表面の汚れを取り除くために、まずツールを温水ですすいでください。

-

石鹸を塗る:少量のマイルドな食器用洗剤を温水に混ぜます。

-

優しくこする:布または歯ブラシを使用して、汚れや垢のある部分を中心にツールを優しくこすります。

-

徹底的にすすぐ:きれいな流水を使用して石鹸の残留物をすべて取り除き、徹底的にすすいでください。

ステップ3: 頑固な汚れを落とす

イソプロピルアルコールに浸した綿棒を使用して、表面の粘着性または頑固な残留物を優しく拭き取ります。

ステップ4:完全に乾かす

洗浄後は、マイクロファイバータオルを使用してツールを完全に乾かします。長期的な損傷を防ぐために、すべての隙間と接合部に湿気がないことを確認してください。

ステップ5: 徹底的なクリーニング(オプション)

複雑なデザインのツールや届きにくい場所のツールには、超音波洗浄機の使用を検討してください。水とチタンに安全な洗浄液を入れて、指示に従ってください。

徹底的なクリーニングは、ツールの機能を回復するだけでなく、新鮮で磨き上げられた外観を与えます。この手順を時々実行することで、特に頻繁に使用するツールの場合、大きな違いが生まれます。

チタン工具の保管

EDC ギアの品質を維持するには、適切な保管が重要です。ツールを効果的に保管する方法は次のとおりです。

-

安全な保管場所を選択してください:ツールは、極端な温度や湿度を避け、乾燥した涼しい環境に保管してください。

-

保護ケースを使用する:傷やへこみを防ぐために、高品質の保護ケースまたはポーチを購入してください。

-

化学薬品への長時間の曝露を避ける:長時間の曝露は仕上げに影響を及ぼす可能性があるため、ツールを強力な化学薬品から遠ざけて保管してください。

-

ギアを整理する:仕切りやコンパートメントを使用してツールを分けて保管し、偶発的な傷や損傷を防ぎます。

ストレージルーチンの作成

使用後はツールを所定の保管場所に戻す習慣をつけましょう。この習慣はツールを安全に保つだけでなく、必要なときに簡単に見つけられるようにします。時間が経つにつれて、この習慣がもたらす整頓性と耐久性の恩恵を受けるでしょう。

最適な保管環境を構築することで、ツールを不必要な損傷から保護し、新品同様の状態を維持できます。

予防メンテナンスのヒント

1. ツールを定期的に点検する

工具に摩耗や損傷の兆候がないか、定期的に点検してください。緩んだ部品、鈍い刃など、パフォーマンスに影響する可能性のある問題がないか確認してください。定期的な点検は、潜在的な問題を早期に発見するのに役立ちます。

2. 可動部品に潤滑油を差す

チタン製ツールがスムーズに動作し続けるように、ヒンジやブレードに少量の潤滑剤を塗布してください。最良の結果を得るには、チタンに安全な潤滑剤を使用してください。ほこりが付かないように、余分な油は必ず拭き取ってください。

潤滑は、屋外や作業場などの厳しい環境で使用されるツールにとって特に重要です。潤滑は摩擦を防ぎ、一貫したパフォーマンスを保証します。

3. 必要に応じて刃を研ぐ

チタン製のナイフや刃物のある工具は、研ぐことが不可欠です。刃物を最高の状態に保つには、砥石を使用するか、専門の研磨サービスを利用してください。常に、特定の工具に適した研磨角度に従ってください。

4. 過酷な衝撃を避ける

チタンは耐久性に優れていますが、繰り返し衝撃を与えたり、誤った使い方をすると損傷する可能性があります。不要な負担を避けるために、ツールは本来の用途に沿って使用してください。たとえば、マルチツールの刃をこじ開けたり、てこを使ったりするのに使用しないでください。

5. 使用後はすぐに洗浄する

さっとすすいで拭くだけで、仕上がりを保つことができます。

6. ツールをローテーションする

複数の EDC ツールを所有している場合は、1 つのツールを使いすぎないように、ツールをローテーションして使用することを検討してください。この方法により、コレクション全体で摩耗が均等に分散され、すべてのツールが長持ちします。

7. 傷から守る

ポケットやバッグに入れて持ち運ぶことが多い工具には、他の物による摩耗を防ぐために保護カバーやスリーブを使用してください。このような簡単な対策で、不要な摩耗を防ぐことができます。

高度なメンテナンス方法

チタン工具の研磨

時間が経つと、チタンには小さな傷がついたり、光沢が失われたりすることがあります。輝きを取り戻すには、次の手順に従ってください。

-

チタン用に設計された非研磨性の研磨布またはコンパウンドを使用してください。

-

傷のある部分を中心に、円を描くようにポリッシュを塗ります。

-

マイクロファイバーの布で拭くと、表面がリフレッシュされます。

このステップは、EDC ギアの美的魅力に誇りを持っている人にとって特に有益です。

パーソナライズのための陽極酸化処理

陽極酸化処理により、チタン製ツールに鮮やかな色を加えることができます。この処理では、電気的な負荷を利用して表面の酸化層を変化させ、独特の色合いを作り出します。ご興味があれば、完璧な仕上がりのためにプロの陽極酸化処理サービスを検討してください。

よくある落とし穴を避ける

チタンのメンテナンスに慣れていない場合、ツールの手入れの際に間違いを犯しがちです。よくある間違いを避けるためのヒントをいくつかご紹介します。

-

小さな詳細を見逃さないでください:小さな傷や緩んだネジでも、無視すると事態が悪化する可能性があります。これらの問題にはすぐに対処してください。

-

掃除中は優しく行ってください。汚れがひどい場合でも、強くこすったり、過度の力を加えたりしないでください。

高度な清掃技術

一般的なメンテナンスには定期的な清掃で十分ですが、次のようなシナリオでは高度な技術が必要になります。

緑青の除去

時間が経つと、チタン製の工具に緑青が現れることがあります。これは錆ではなく、環境要因に対する反応です。元の仕上げを復元するには、次の手順に従います。

-

重曹と水を使ってペーストを作ります。

-

変色した部分に塗布し、柔らかい布で軽くこすります。

-

ぬるま湯でよくすすいで、すぐに乾かしてください。

油汚れや粘着性残留物への対処

ツールにグリースや粘着性の残留物が蓄積した場合は、温水とイソプロピルアルコールの混合液が役立ちます。マイクロファイバーの布を溶液に浸し、汚れた部分を拭き、乾いた布で拭き取ります。

アウトドアアドベンチャー中のメンテナンス

多くのEDC愛好家は、ハイキング、キャンプ、釣りなどのアウトドア活動中にチタン製のツールを使用します。このような場合、メンテナンスはさらに重要になります。

塩水への曝露への対処

塩水は工具にミネラルの堆積物を残すことがあります。塩水にさらされた後は、工具を真水で洗い流し、完全に乾燥させてください。保護を強化するために、可動部分に潤滑剤を薄く塗ってください。

土砂の管理

屋外での活動では、ツールが汚れや砂にさらされることが多く、ジョイントや隙間に詰まることがあります。柔らかい毛のブラシまたは圧縮空気を使用してゴミを取り除き、湿った布で優しく拭いてください。

定期メンテナンスの価値

定期的なメンテナンスは、これらの重要なツールとのつながりを強化する儀式になります。定期的に少しの時間を割くことで、将来的にさらに重大な問題を回避できます。

ツールは単なる機能的なアイテムではなく、あなたのスタイルと品質へのこだわりを反映するものなのです。